New Driver-in-the-Loop simulator for Voice of the Customer vehicle attribute engineering

HORIBA MIRA’s Vehicle Attribute Development Team invests in class-leading VI-grade simulator

- New hardware key to enhancing virtual series design & development

- The simulator will bring the driver experience forward in the development process

- Facility will shorten physical development time and cost and improve vehicle performance for OEM & Tier 1 customers

- Now commissioned for handling & steering development

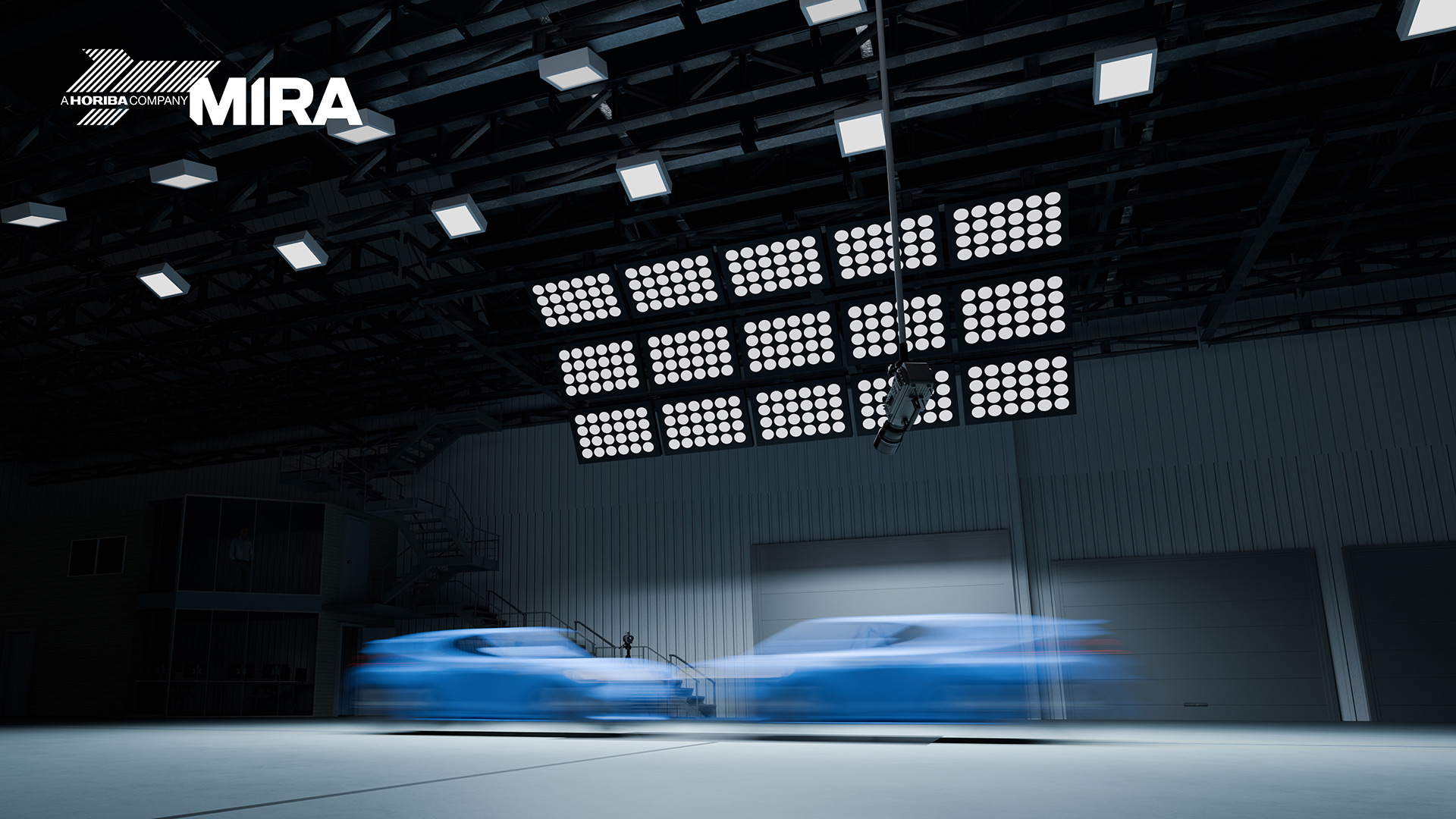

The new VI-grade simulator now operational at HORIBA MIRA’s Vehicle Development & Attribute Engineering facilities

Nuneaton, Warwickshire. Europe’s leading automotive engineering consultancy, HORIBA MIRA, today confirmed that its Vehicle Attribute Development Team had concluded an investment in a new VI-grade COMPACT simulator to underscore its proprietary Voice of the Customer approach to vehicle development.

The foundation of HORIBA MIRA’s attribute engineering process is focused on the driver experience as the key determiner of engineering decisions; the new Driver-in-the-Loop capability further embeds this philosophy by incorporating the driver’s subjective assessments at the earlier, virtual stage of the design cycle.

Tom Lee, Vehicle Dynamics and NVH Manager at HORIBA MIRA said,

“Adding the driver into the loop at an earlier stage in the virtual development phase not only results in better overall engineering decisions, but it is wholly consistent with our Voice of the Customer approach to attribute engineering. This investment in our new simulator facility underlines our ongoing commitment at HORIBA MIRA to remain the market leaders by utilising the knowledge, experience and quality of our engineers with the latest engineering tools required to deliver first-class results for our customers.”

Guido Bairati, VP Global Sales & Marketing at VI-grade said,

“We are happy to confirm the adoption and installation of our COMPACT Simulator at HORIBA MIRA. This demonstrates that testing activities and simulation are converging to develop better cars in shorter timeframes. Driving simulators provide engineers with subjective feedback earlier in the design cycle, enhance later-stage prototype testing and help to anticipate potential issues. The level of accuracy of VI-grade driving simulators make it possible to develop, test and fine-tune new vehicles with a precision never seen before.”

The VI-grade facility has been fully commissioned and is now operational as part of the company’s Vehicle Attribute Development Team’s services. The solution will ensure test and development timelines are shortened, costs are reduced and ultimately product performance is enhanced for the company’s OEM and Tier 1 customers.