HORIBA MIRA Develops High Voltage Commercial Battery Using Nissan’s Leaf Cell Technology

HORIBA MIRA – a world-leader in advanced engineering, research and product testing – has partnered with electric vehicle pioneer, Nissan, to develop a commercial vehicle battery system for hybrid buses, trucks, defence and off-highway systems.

The Nickel Manganese Cobalt Oxide (NMC) Lithium ion cells utilised in this battery pack are the latest generation technology, almost doubling the energy density from previous generations. This allows us to produce a smaller, lighter battery pack whilst increasing vehicle range.

The battery is suitable for a variety of electric and hybrid vehicle applications and can be delivered in a range of capacities from 67kWh through to 400kWh. Prototype batteries will be available in early-2018, with the potential for volume supply in 2019.

The battery was first developed as part of a collaborative project with Dennis Eagle, leading manufacturer of specialist vehicles in the UK, for the Urban Vehicle Range (UVR) programme. The UVR project is developing a range of low emission and fuel efficient vehicles for waste collection applications. The project will deliver three prototype variants: a lightweight IC engine vehicle, a Compressed Natural Gas (CNG) vehicle and a plugin hybrid vehicle.

Dr. George Gillespie OBE, CEO at HORIBA MIRA, said:

“This project brings Nissan’s latest Leaf cell technology into new markets, harnessing HORIBA MIRAs expertise in battery pack development to deliver this highly efficient battery technology to bus, coach, truck and off-highway sectors. Efficient and cost effective lithium ion battery technology is key to accelerating the uptake of hybrid and electric vehicles, and this development takes us one step closer to hitting the UK targets for emission reduction in the commercial vehicle sector.”

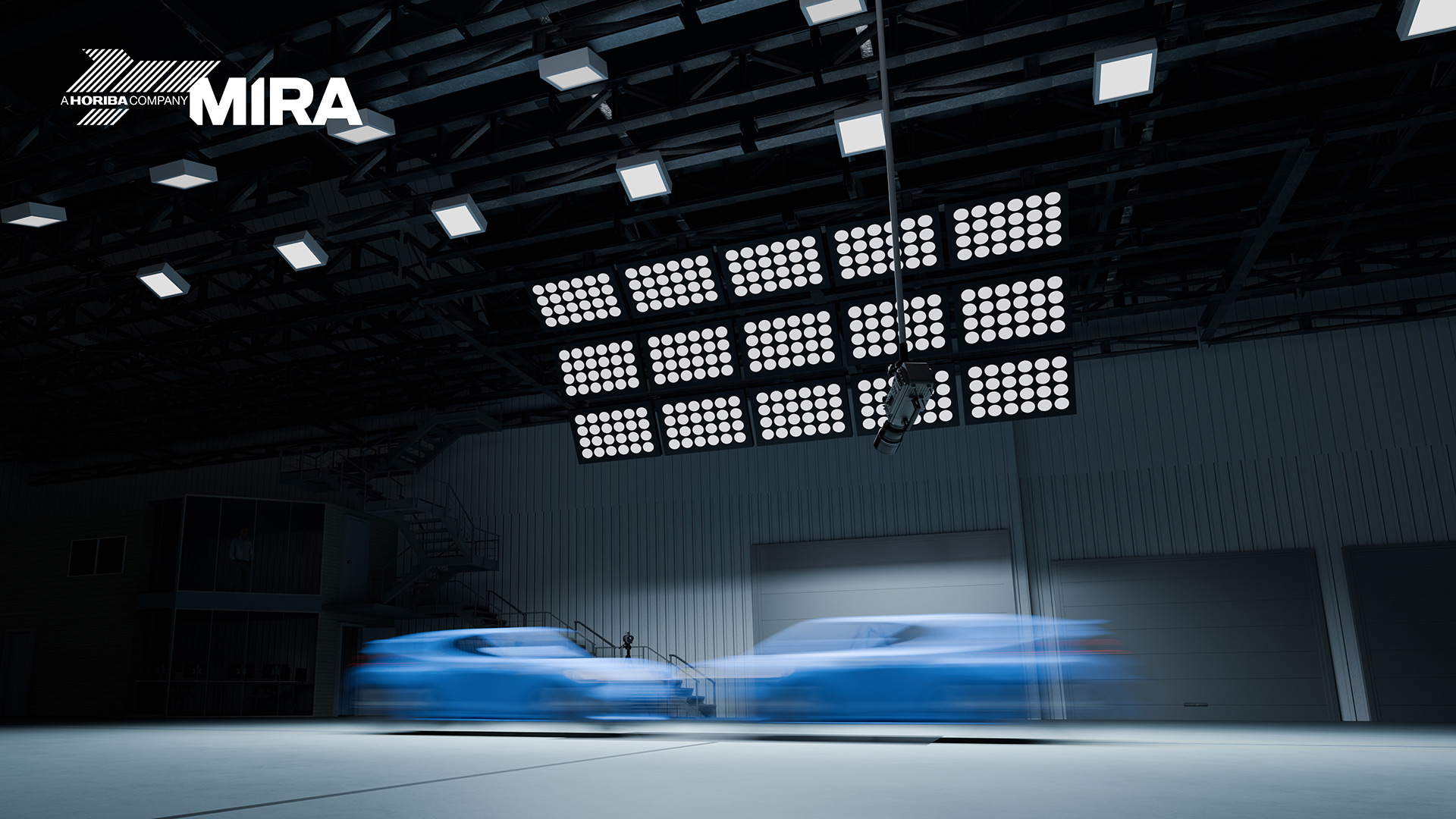

This announcement follows news of HORIBA MIRA’s ground-breaking Advanced Battery Development Centre which started construction last month. The facility will provide complete battery pack testing, simulated battery pack testing, integration testing and development of powertrain and battery packs at system level including EMC characterisation.