Approach

The test programme had already begun in the UK when the decision was taken to relocate the testing to the Netherlands. With the EU deadline to complete this test programme before the end of 2022, the race was on for HORIBA MIRA’s engineering team to complete the testing of nine machines in just six weeks.

HORIBA MIRA located a suitable facility in the Netherlands that could accommodate the testing at short notice. Appropriate machines that had performed a representative amount of real-world use were sourced and shipped to the facility, along with the personnel and equipment required to support the test. This bespoke service relieved the OEM from the pressure and burden and ensured the testing could be achieved within their tight timeframe with minimal input from the OEM.

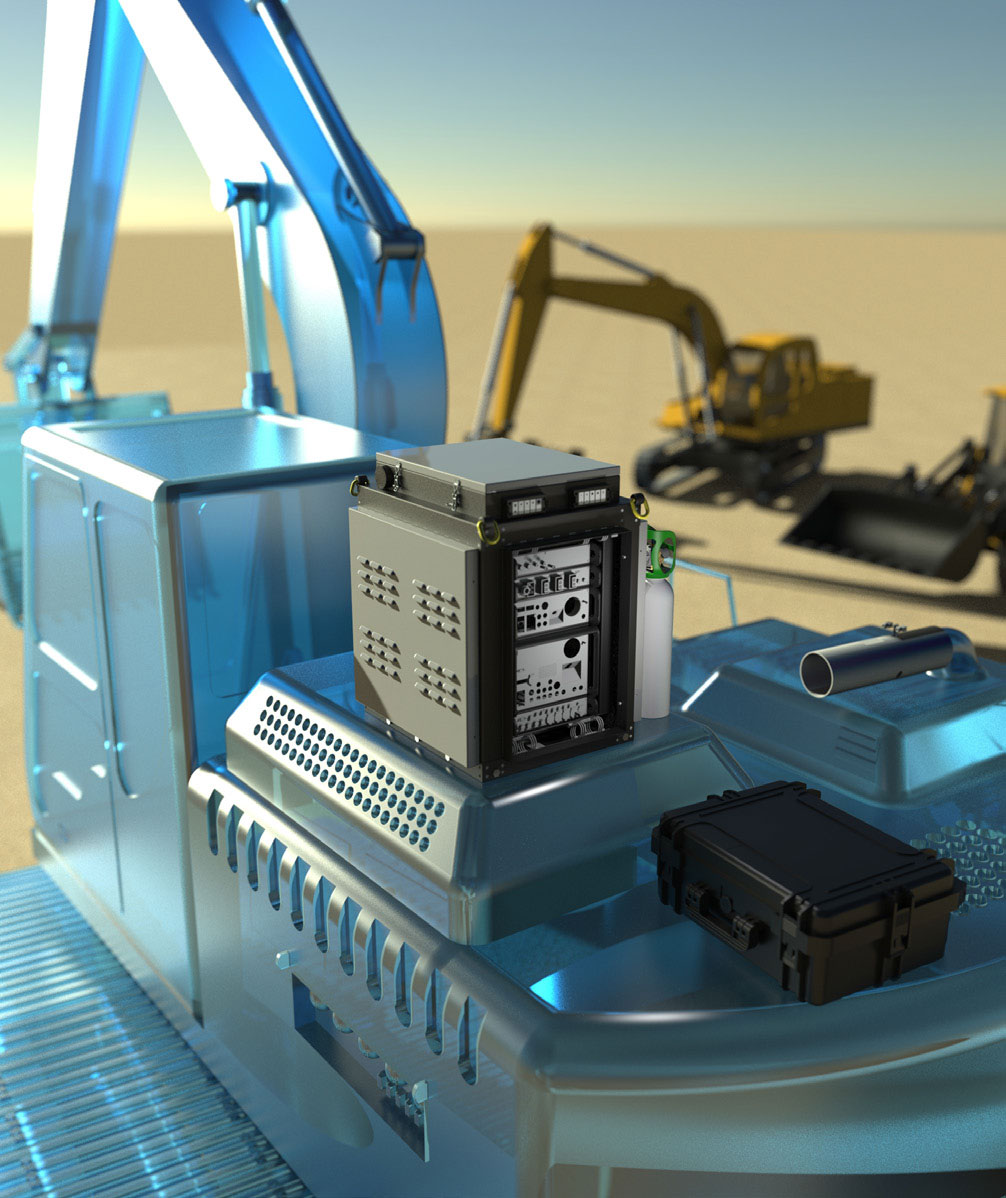

The work drew upon HORIBA MIRA’s vast experience of using Portable Emissions Measuring Systems (PEMS) for on-road vehicle testing. Working with specialist HORIBA measurement equipment, the team was able to successfully test the machinery in the harsh environment that mimics a construction site.

For instance, testing was performed using HORIBA’s specialist ‘Rugged Enclosure’ for the OBS-ONE PEMS measurement system, which ensured accurate, reliable, and robust measurement of exhaust emissions, in an environment that’s subject to challenging conditions such as severe dust and vibration.

Successes and benefits

The success of this project in a heavily constrained timescale depended on HORIBA MIRA’s expertise with emissions testing in harsh environments, plus the team’s ability to react to changing circumstances in an agile manner. Key benefits included:

- Access to consultancy from technical specialists with proven experience.

- Access to specialist test equipment capable of providing high quality, accurate and reliable measurement data in a harsh environment with a high test success rate.

- An end-to-end service, including sourcing the vehicles and carrying out all testing, which removed any risk from the customer’s perspective.

- In-house engineering expertise, capable of safeguarding against unforeseen circumstances during the test and supporting any follow-up work.

HORIBA MIRA is uniquely positioned to provide in-service emissions testing for off-highway machines. In this instance, we had to take an agile approach and carry out a lot of risk management to ensure the results were delivered on time, amid a complex multi-country logistical situation.

Commercial Manager, HORIBA MIRA