The journey from apprentice to engineer – An overview for STEM learners

Alisdair Bowie – Senior Software and Controls Engineer, joined HORIBA MIRA in 2011 after achieving a degree in Mechanical Engineering. Alongside his role in Software and Controls where he primarily develops control software for hybrid and electric vehicles, Alisdair is working to inspire children through his work as a STEM (Science, Technology, Engineering and Mathematics) Ambassador. As a STEM Ambassador, Alisdair volunteers his time and enthusiasm to help bring STEM subjects to life for young people. Here, Alisdair shares the story about how one of his colleagues, Paul Ingle became an engineer following an apprenticeship.

From birthday cards to electric buses via super formula: The journey from apprentice to engineer

In my ‘How did I become an engineer?’ blog I described my journey into engineering via the ‘graduate route’ and mentioned that there are other paths into the profession. In this blog I’d like to describe the apprenticeship route taken by one of my colleagues, Paul Ingle, a Principal Engineer in our Software and Controls team.

Let me take you back to the late 1970s. Flared trousers started to go out of fashion, Margaret Thatcher had become prime minister of the UK, the internet was still in its early research and development phase (Google hadn’t been invented yet) and both the second oil crisis and Queen rocked the world (albeit in different ways).

On the outskirts of Leeds, a young Paul was fascinated by how different things around the house worked, particularly electronic components. Frequently taking things apart and putting them back together again, Paul’s curiosity helped develop a lot of useful skills, but it wasn’t always successful…

On a caravan holiday, an attempt to re-wire a digital clock from a wall plug to the 12V supply of the caravan resulted in the said clock transforming into a slightly less useful paperweight! The way Paul managed to convince his folks the clock broke all on its own remains one of the best cover ups since the Roswell UFO incident.

After leaving school with seven O-levels (now GCSEs) Paul joined Dean Smith & Grace, a manufacturer of lathes, as an apprentice electrical technician engineer. At school, Paul felt he learned best using a hands-on approach so felt an apprenticeship was the best way to learn the skills needed to become an engineer. During Paul’s apprenticeship, he moved around all areas of the business which helped Paul to understand what the entire business did, rather than one specific department.

Broadening his skills, trying new things, appreciating other teams’ requirements and using varied experiences to come up with new solutions to problems, were just some of the experiences Paul got out of his apprenticeship.

Another benefit was being able to practically apply the theory he had learned in the classroom, enabling him to get hands-on experience from day one. This meant by the end of the apprenticeship Paul felt he was a more grounded engineer and had a deeper understanding of what he’d learnt and how it is applied in the real world.

In the summer of 1991, after four years and having achieved an ONC and then an HNC in Electrical and Electronic Engineering at college, Paul decided to move on to Kingsley Cards in Skipton, North Yorkshire.

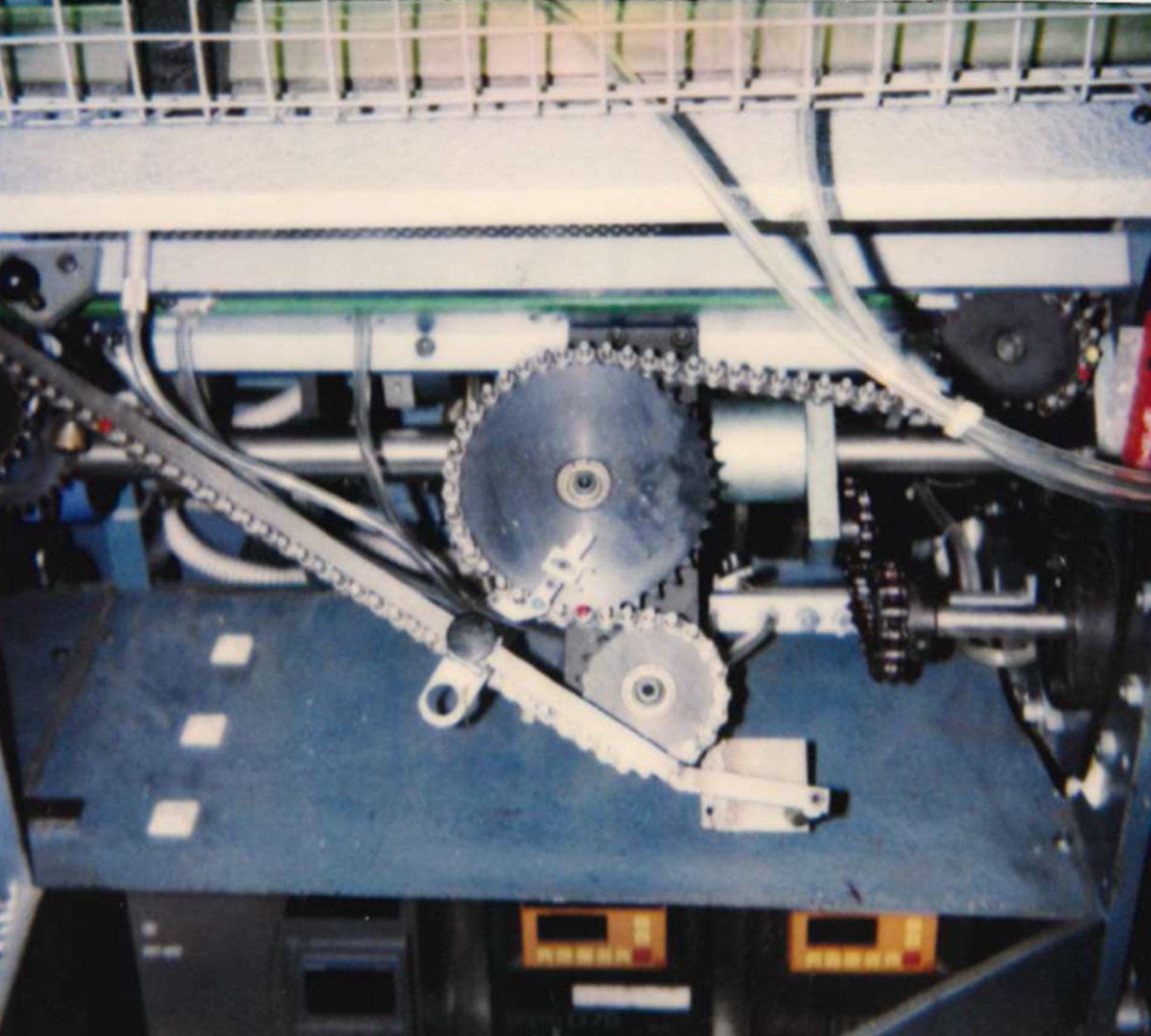

Kingsley Cards was a greetings card manufacturer and one of Paul’s duties was to re-engineer a machine which stuck greetings card insert pages into the cards before being shipped to shops around the UK. Previously the machine had cams which moved the cards into position, but this wasn’t reliable, so Paul came up with an innovative dual motor system which provided a much smoother operation.

I should add here that he did this while studying part-time for a BSc in Electronic Control Systems Engineering at Leeds Metropolitan University (now Leeds Beckett University) at which Paul’s improved card machine became the subject of his thesis. During eight years with the company, Paul rose from Maintenance Electronics/Development Engineer to Engineering Manager. He’s a hard worker is our Paul!

Paul’s new card inserting machine, ~1997

With card inserts now heading into cards in a much smoother fashion, Paul decided to begin his journey southwards and started his career in the automotive industry by joining Wabco Automotive in Morley, West Yorkshire. Now this was a job!

Paul’s role was to listen to what solutions customers needed and no matter how wacky, try and find solutions to them. Prizes were awarded for the most ridiculous idea at the end of every year!

This was pure problem solving and what engineers are best at! Although, it wasn’t all hard work was it, Paul…?

After two and a half years at Wabco, Paul continued his voyage southwards and joined Zytek Automotive in Lichfield, Staffordshire in 2001.

Paul started at Zytek as a software development engineer creating embedded software for electric vehicles (yes, they were around in the early 2000s too). In this time, Paul developed a control strategy for an electric motor, destined for various vehicles such as small city cars, mini-buses, delivery vans, sports cars and even a formula student car. In 2002, Paul’s many achievements were recognised and he became a chartered engineer with the Institution of Electrical Engineers, now the IET.

Paul rose through the ranks to principal application engineer and worked on interesting projects that took him to far flung places like Sweden for cold weather testing and Japan, to develop gearbox controllers for the Japanese Super Formula championship.

At Zytek, Paul learnt the importance of testing in a controlled environment…

On an outing with a prototype vehicle running Paul’s software, things were going okay until the test driver touched the brake. Instead of slowing the car down, pressing the brake pedal surprisingly caused full acceleration! After a bit of investigation (and presumably a few moments to regain some composure) Paul discovered this was caused by memory overflow in the control software. Safe to say, it’s never happened again!

In Sweden, during cold weather testing on a vehicle in a chilly -25oC, Paul was using his laptop on the roof of the car, with a USB cable running across the roof of the car. When testing was finished and it was time to remove the laptop and cable, the cable had frozen, meaning Paul had to carry a 2m long frozen cable back to the office to avoid snapping it!

Honda Super Formula Car at Fuji Speedway, 2013

Sweden, 2015

Despite scaring test drivers and freezing cables, Paul stayed with Zytek for 14 years before deciding to move on. He joined us here at HORIBA MIRA in 2015. Since joining, Paul has been leading teams developing software for vehicles as varied as hybrid refuse collection vehicles (bin lorries) and electric buses for customers all around the world.

Paul now leads a team in our software and controls team working on various projects helping customers develop safer, cleaner and smarter vehicles. Paul is now responsible for setting engineering deliverables, project proposals, and organising, promoting and developing the capabilities of his team.

Paul says: “The variety and challenges mean every day is different and always unique in some way.” As with many colleagues at HORIBA MIRA, Paul finds this motivating and continuously stimulating. I asked if that was because he works with me, but he never confirmed that…

Paul’s career story (so far) has certainly been interesting and it all started in 1987 with an apprenticeship. Apprenticeships are a fantastic way of combining on-the-job learning with the theory learned through formal education. In hindsight, I wish I had done an apprenticeship.

When young people ask me what you can achieve if you start your career through an apprenticeship the answer I always give is ‘whatever you believe you can’. As Paul’s career has shown; if you have a good attitude and are prepared to work hard there is nothing that you can’t achieve.

Over the years, Paul has learned a few lessons he would like to pass onto anyone keen on a career in engineering:

- A sound academic education is a necessary foundation. Having the ability to apply it in real life is absolutely essential

- Always treat people how you would like to be treated yourself

- When faced with a problem, don’t be afraid to ‘think outside the box’, see the bigger picture and be open minded to alternative approaches

- Mistakes are a learning opportunity and we all make them. Never be afraid to hold your hand up and admit you got it wrong. Remember; those who never made a mistake never did anything!

HORIBA MIRA has a strong history of recruiting apprentices and some of our most senior staff started their careers as an apprentice. If you are interested in an apprenticeship at HORIBA MIRA and joining colleagues like Paul and myself, keep an eye on the future talent section of our website for more details and vacancies.